Web Menu

Product Search

Exit Menu

Blog

Home / News & Blog / Blog / 10 Things You Should Know About Cenwan High Speed Folder Gluer

10 Things You Should Know About Cenwan High Speed Folder Gluer

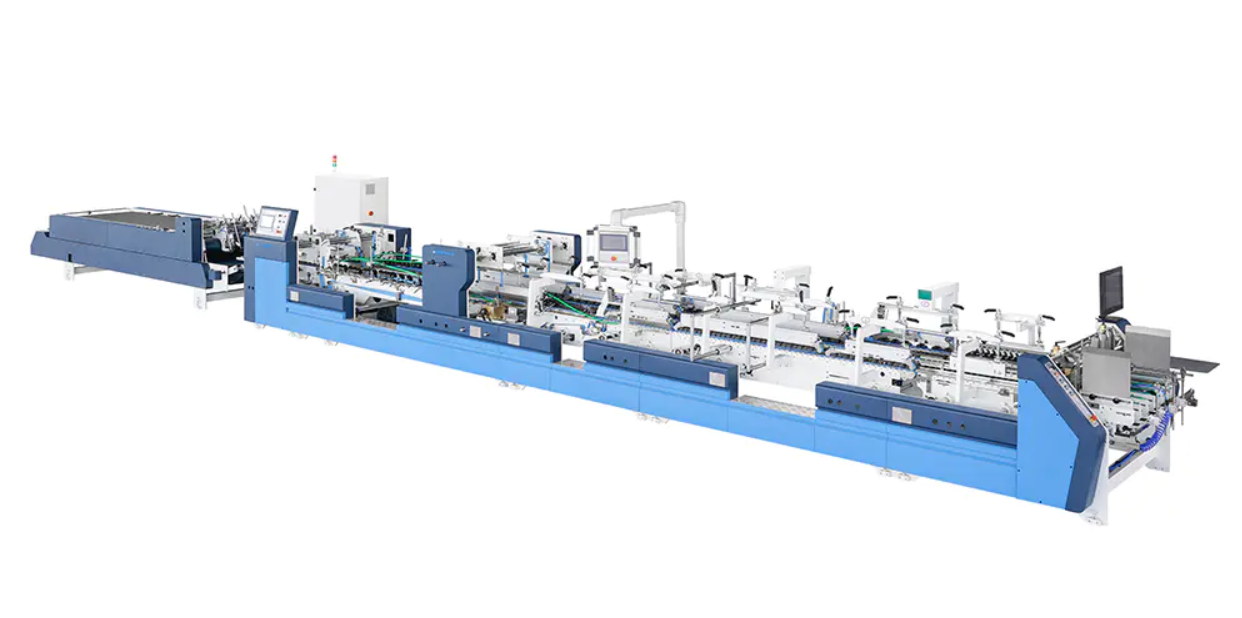

In today’s industrial world, speed and precision are not just business advantages—they are survival tools. Packaging, once a manual and time-consuming step in manufacturing, has now evolved into a highly automated process. This evolution is largely thanks to machines like the High Speed Folder Gluer, which have become central to folding carton production.

Whether you walk into a pharmaceutical packaging line, a cosmetics plant, or a food and beverage factory, chances are you’ll find a folder gluer running in the background. These machines quietly and efficiently transform flat sheets of paperboard into ready-to-use cartons. For many companies, investing in a High Speed Folder Gluer is no longer a luxury but a necessity for meeting deadlines, reducing errors, and scaling operations.

This blog will take a deep dive into what makes the High Speed Folder Gluer so important, how it works, where it fits in modern manufacturing, and why it is shaping the future of packaging.

Chapter 1: What Exactly Is a High Speed Folder Gluer?

A High Speed Folder Gluer is a piece of equipment designed to fold and glue cartons at rapid speeds. Unlike traditional manual or semi-automatic methods, this machine delivers consistent, precise, and scalable results. It handles multiple types of carton designs, including straight-line boxes, crash-lock bottoms, and four- or six-corner boxes.

Its core function sounds simple: fold the carton and apply adhesive. But in reality, the machine integrates mechanical precision, automation, and digital controls to ensure every carton is uniform. For industries that rely on consistent packaging to protect products and present them attractively on shelves, this reliability is invaluable.

Chapter 2: Why Speed Matters in Packaging

Time is money in manufacturing. A major appeal of the High Speed Folder Gluer lies in its ability to process thousands of cartons per hour. Large-scale producers often face tight deadlines, and traditional methods cannot match these volumes without compromising quality.

A High Speed Folder Gluer keeps the line moving. Imagine a food packaging company preparing for a seasonal surge in demand. With the right setup, this machine can keep pace without bottlenecks, ensuring cartons are ready to be filled, sealed, and shipped on time.

But speed alone is not the full story. The machine maintains accuracy even at high output. Each fold is sharp, each adhesive line is consistent, and each finished carton matches design specifications. This dual advantage—speed and precision—explains why the High Speed Folder Gluer has earned its place on factory floors worldwide.

Chapter 3: Versatility Across Materials and Industries

Another reason the High Speed Folder Gluer stands out is its flexibility. Modern models are designed to handle a wide range of materials:

-

Solid board for cosmetics and pharmaceuticals

-

Corrugated board for e-commerce and heavier goods

-

Laminated substrates for premium packaging

This adaptability allows manufacturers to use one machine for multiple product lines. For example, a company producing both snack boxes and luxury skincare cartons can adjust the settings of the same folder gluer to handle each task efficiently.

Industries benefiting from High Speed Folder Gluers include:

-

Pharmaceuticals: Where accuracy in packaging is critical for safety and compliance

-

Food & Beverages: Where speed is essential to meet demand surges

-

Cosmetics: Where flawless packaging enhances brand image

-

Electronics: Where protective and reliable cartons reduce product damage

Chapter 4: User-Friendly Design and Smart Features

One misconception about advanced machinery is that it requires complex training. High Speed Folder Gluers challenge this idea. Many models come equipped with:

-

Touchscreen interfaces that allow operators to adjust settings with ease

-

Automated setup systems that minimize downtime when switching carton types

-

Diagnostic alerts that notify staff of maintenance needs

This user-centric approach reduces the learning curve for operators. Companies do not need to invest months into training staff; instead, they can integrate the machine quickly into existing workflows.

Chapter 5: Built for Long-Term Use

Packaging lines often run for long hours under demanding conditions. That’s why durability is crucial. High Speed Folder Gluers are built with robust frames, precision parts, and high-quality materials that withstand continuous operation.

Regular preventive maintenance, such as lubrication and calibration, ensures that the machine delivers stable performance over years. Even in environments where production demands fluctuate, these machines offer dependable uptime and minimal unexpected downtime.

Chapter 6: Sustainable Packaging Through Automation

Sustainability is no longer optional. Companies face pressure from consumers, regulators, and investors to minimize their environmental impact. The High Speed Folder Gluer contributes to greener manufacturing in several ways:

-

Reducing waste by folding cartons correctly the first time

-

Minimizing rework through consistent quality control

-

Offering energy-efficient models that lower electricity usage

For businesses aiming to balance profitability with responsibility, this machine aligns perfectly with long-term sustainability goals.

Chapter 7: Tailored to Specific Needs

Not every manufacturer produces the same type of carton. That’s why High Speed Folder Gluers are often customizable. Options may include:

-

Special folding attachments for unique designs

-

Gluing systems for hot-melt or cold adhesives

-

Barcode readers for traceability and inventory tracking

This ability to customize enhances the versatility of the equipment, making it suitable for both niche packaging firms and large-scale producers.

Chapter 8: Quality Control at the Core

Defective cartons not only increase costs but also damage brand reputation. High Speed Folder Gluers integrate sensors and monitoring systems that automatically detect misfolded or unglued cartons. These units are rejected before leaving the line, ensuring only quality products reach the market.

The result is fewer returns, higher customer satisfaction, and greater trust in the brand. In industries like pharmaceuticals, where packaging errors could compromise safety, this feature is non-negotiable.

Chapter 9: Calculating the Return on Investment

A High Speed Folder Gluer may appear to be a significant upfront investment, but the ROI is often strong. Savings come from several areas:

-

Lower labor costs due to reduced manual intervention

-

Fewer material losses from defective cartons

-

Higher throughput enabling companies to take on more orders

Many businesses report noticeable improvements in profitability within the first year of adopting the technology. For small and medium enterprises, this can be the step that transforms them from struggling to thriving.

Chapter 10: Looking Ahead – The Future of Folder Gluer Machines

Technology never stands still. Future developments in High Speed Folder Gluers are expected to integrate with Industry 4.0 concepts:

-

IoT connectivity, allowing real-time monitoring and remote troubleshooting

-

Artificial intelligence, helping machines predict maintenance needs before breakdowns

-

Advanced robotics, making setups even faster and more precise

The packaging industry will likely see even smarter, greener, and more efficient machines in the coming years.

->More Than Just a Machine

The High Speed Folder Gluer is more than a piece of equipment—it is a cornerstone of modern packaging automation. By combining speed, accuracy, durability, and sustainability, it empowers companies to keep up with consumer demands while staying competitive in a global market.

For businesses considering their next move in packaging automation, the question is not whether to invest in a High Speed Folder Gluer, but when. The future of efficient, eco-friendly, and scalable packaging starts here.

Recommended Products

Focus on providing high-quality folder-gluing equipment to customers around the world.

-

-

-

No.3888, Jiangnan Avenue, Nanbin Street, Ruian City, Wenzhou City, Zhejiang Province, China

English

English русский

русский Français

Français Español

Español Deutsch

Deutsch