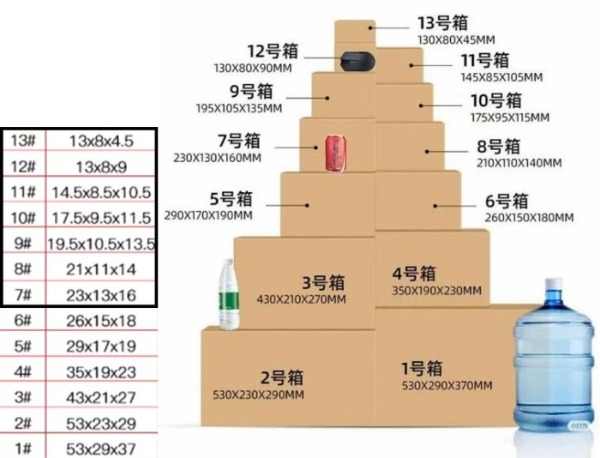

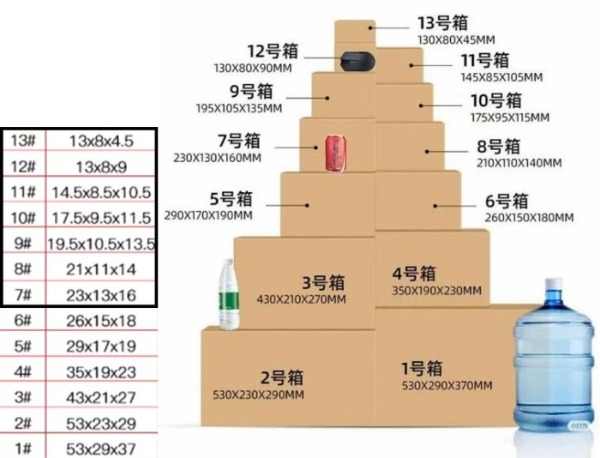

The equipment is precisely adapted to produce the full range of express carton sizes 7-13, ensuring a stable response to both the massive volume of carton orders during e-commerce promotions and regular express packaging needs. Its core components are manufactured with high-precision craftsmanship and are equipped with internationally renowned electrical components and bearings. This ensures exceptional stability and durability, even at high speeds, effectively reducing failure rates and maintenance costs.

1 All transmission bearings in the entire machine are assembled using a temperature differential assembly process, resulting in more precise transmission and a longer service life.;

2 It is suitable for a variety of carton sizes from No.7 to No.13,which meets market common needs;

3 Machine utilizes servo motors to ensure high production efficiency and operational stability;

4 Universal tools are integrated, allowing the entire machine to be installed and debugged using a single tool, making machine adjustment and installation easier and more convenient.

5 Custom models are available, with optional features as one-click adjustment.

|

Model

|

Die Cutting Part

|

|

Applicable Paper

|

E,N,F Corrugated Board

|

|

Mechanical inner width

|

2000mm

|

|

Controller Method

|

PLC human-machine interface control

|

|

Max Cutting Speed

|

180pcs/min

|

|

Max Feeding Width

|

1700mm×1200mm

|

|

Power Required

|

20KW

|

|

Main Functions

|

Paper feeding, die cutting, stacking, conveying

|

|

Paper Feeding Method

|

High-pressure centrifugal fan suction assists paper feeding

|

|

Model

|

Folder Gluer Part

|

|

Applicable Paper

|

E,N,F Corrugated Board

|

|

Max Cardboard Thickness

|

800g

|

|

Paper Feeding Method

|

Compatible with rotary slotter die cutting machine with waste removal

|

|

Max.Box Gluing Speed

|

240m/min

|

|

Box Making Width

|

450-750mm

|

|

Machine Dimensions

|

17.5×4×1.8(L×W×H/M) for whole line

|

|

Glue type

|

Solute-Type (White latex)

|

|

Total Weight(Approx.)

|

16T for whole line

|

|

Power Required

|

20KW

|

|

Air Pressure

|

6Pa

|

FAQ

- Q: Are you a trading company or a manufacturer?

We are a manufacturer with our own factory and workers.

- Q: What types of machines do you produce?

We offer various types of Folder Gluer Machines, including models customized for different box types such as cardboard and corrugated boxes.

- Q: Where is your factory located? How can I visit?

Our factory is located in Wenzhou City, Zhejiang Province, China. The nearest airport is Wenzhou Longwan International Airport, about a 40-minute drive from our factory.

- Q: What’s the price?

It depends on the specific model and configuration. Please provide the box type and size specifications so we can offer an accurate quote or suggestion.

- Q: How do I pay for my order?

Normally, we accept T/T (30% deposit before production and the balance before shipment). But we can also accept other payment methods like L/C, credit card as per you request.

- Q: What is your minimum order quantity?

1 set.

- Q: What is the delivery time?

It will take about 30 days to finish an order. But the exact time is according to actual situation.

- Q: How do you ensure quality and provide after-sales support?

Quality is our top priority. All machines are strictly tested before delivery. We offer a one-year warranty and provide comprehensive after-sales service and technical support. If any issues arise, please contact us immediately and we’ll help resolve them.

- Q: Do you provide installation and staff training services?

Certainly. Our after-sales service includes professional on-site installation and comprehensive staff training conducted by our experienced engineers. To ensure a smooth process, we kindly request that the buyer covers the costs associated with the engineer's travel, including round-trip airfare, local accommodation, daily salary.

To ensure you receive continuous support, our sales team is readily available to schedule instructional video conferences with our engineers throughout the lifespan of your CENWAN equipment. This comprehensive technical support includes live broadcasts from our facility and access to detailed video recordings.

English

English русский

русский Français

Français Español

Español Deutsch

Deutsch